SEER2, Inverter Tech & A2L: What HVAC Contractors Need to Know Now

The HVAC industry is undergoing one of its most significant shifts in decades. Between SEER2 efficiency standards, inverter-driven systems, and the A2L refrigerant transition, there’s a lot to unpack and even more to get right on the job site.

This guide provides HVAC contractors with a clear breakdown of what matters today, outlining the steps to take now to stay compliant and competitive.

What is SEER2 and how does it impact HVAC contractors?

SEER2, which stands for Seasonal Energy Efficiency Ratio, is an updated energy efficiency rating system that better reflects real-world operating conditions. It is now required for all new and replacement residential air conditioning (A/C) and heat pump systems in North America.

It took effect January 1, 2023. It replaces the older SEER metric and uses a tougher testing standard, specifically, one that accounts for higher static pressure during operation. As a result, SEER2 ratings appear lower than the SEER numbers for the same equipment.

As an HVAC contractor, here’s what you need to do:

- Know your region’s SEER2 minimums (usually 13.4 to 14.3).

- Ensure that any pre-2023 SEER equipment still in inventory is compliant with current regulations and legally permitted for installation.

- Explain to customers who notice the number drop that it’s not less efficient, just a new testing standard.

What is inverter technology, and why should contractors care?

Inverter-driven systems adjust compressor speed based on demand, offering better comfort, efficiency, and long-term performance, and they’re no longer just for premium installs.

Instead of turning on and off like fixed-speed systems, inverter compressors ramp up or down to match the heating or cooling need in real time. That means fewer temperature swings, less energy use, and a quieter, smoother-running system.

Here’s why it matters now:

- Inverter systems can save homeowners 30–50% on energy costs.

- They reduce strain on components, helping systems last longer.

- They’re key to meeting SEER2 and cold-climate performance expectations.

- Smart homes and zoning systems work best with inverter-based HVAC.

This isn’t a future trend as it’s already standard across many models. If you haven’t already started installing inverter-driven units, now’s the time.

How do HVAC contractors manage the transition to A2L refrigerant?

As of January 1, 2025, most new HVAC systems are using A2L refrigerants, which are classified as mildly flammable and require new tools, training, and installation procedures.

A2Ls, such as R-32 and R-454B, are replacing R-410A in residential and light commercial systems due to their lower global warming potential. But the shift isn’t just about refrigerant as it changes how systems are handled, installed, stored, and serviced.

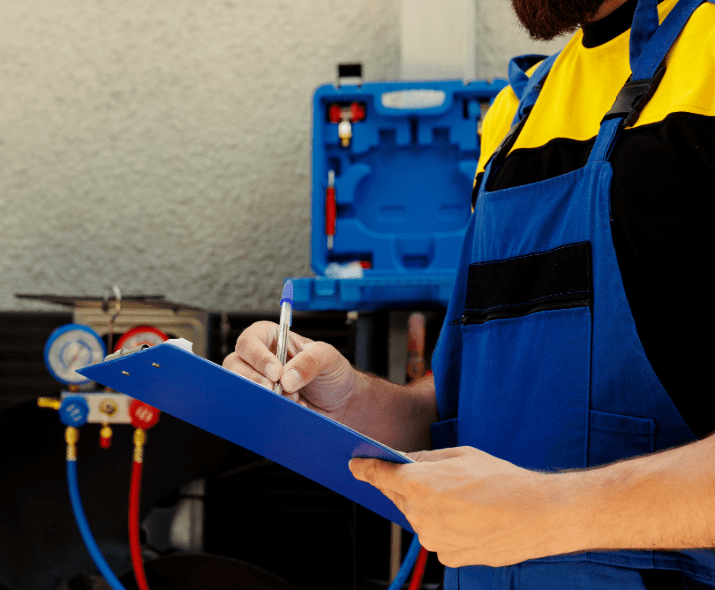

Contractors need to:

- Get certified for safe A2L handling (EPA Section 608).

- Use A2L-rated recovery machines, leak detectors, and manifold gauges.

- Follow new install rules: labeling, piping protection, ventilation, and leak detection (where required).

- Adjust how cylinders are transported and stored, especially in vans or shops.

- Maintain records for code compliance in regulated jurisdictions.

Contractors may have seen recent headlines about ongoing refrigerant shortages impacting residential sales. However, according to Mike Edwards, General Manager at ECCO Supply Sacramento, availability is already improving.

“We’re seeing improvement. Suppliers that previously had restrictions are now allowing mixed pallets of R-32 and R-454B, and minimum order sizes are coming down. That tells me more product is reaching the market and availability is picking up.”

Need help explaining inverter systems to customers? Your ECCO Supply Branch technical service advisor can walk you through key benefits in plain language. You can also ask about A2L-ready tools and training support at your nearest location.